Farm Bureau Members Age Bourbon the Wisconsin Way

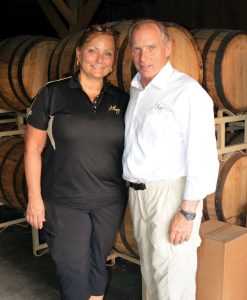

Earlier this year, Dane County Farm Bureau members Joe and Liz Henry introduced their award-winning, Wisconsin-made bourbon to the craft distillery industry. Already established in the seed corn business, their dream of adding a value-added product to the marketplace and agritourism opportunity comes true.

Earlier this year, Dane County Farm Bureau members Joe and Liz Henry introduced their award-winning, Wisconsin-made bourbon to the craft distillery industry. Already established in the seed corn business, their dream of adding a value-added product to the marketplace and agritourism opportunity comes true.

With deep roots in Dane County’s agriculture history including a successful small grain seed and seed corn business started by Joe’s father Jerry in the 1940s, the Henrys along with their sons, Joe and Jack, decided to use the corn, rye and wheat that they grow to make Wisconsin straight bourbon.

The idea sprouted when Joe and Liz toured the Kentucky Bourbon Trail several years ago to learn more about the bourbon industry. Liz recalls traveling around in a rickety school bus filled with people from all across the nation, “some brewers, some distillers, many wannabees just like us, thinking about it and considering a new direction.”

The idea sprouted when Joe and Liz toured the Kentucky Bourbon Trail several years ago to learn more about the bourbon industry. Liz recalls traveling around in a rickety school bus filled with people from all across the nation, “some brewers, some distillers, many wannabees just like us, thinking about it and considering a new direction.”

“I started thinking about a value-added product because we already grew the corn, wheat and rye,” Joe said. “I thought that maybe this could come to fruition.”

Liz, who grew up in Racine and served as the 39th Alice in Dairyland, explained that besides being distilled in the U.S., there are certain rules that must be followed when distilling bourbon

that include the following.

• It can only be aged in new, charred oak barrels.

• The mash bill or recipe must include at least 51 percent corn.

• It has to age for at least two years in order to call it bourbon.

• It has to be distilled to 160 proof or less, barreled at 125 proof or less and bottled at 80 proof or more.

The Henrys decided to use Wisconsin white oak for the barrels, which are made by a cooperage (barrel maker) in Louisville, KY.Because the barrels for the Henry’s bourbon can only be used once, they first shipped the used barrels to Scotland to be recycled for making Scotch but now they are aging proofing water in the used barrels.

The Henrys decided to use Wisconsin white oak for the barrels, which are made by a cooperage (barrel maker) in Louisville, KY.Because the barrels for the Henry’s bourbon can only be used once, they first shipped the used barrels to Scotland to be recycled for making Scotch but now they are aging proofing water in the used barrels.

With this attention to details, a leap of faith, lots of patience and a taste for quality bourbon, the Henry family is producing an award winning, Wisconsin-made bourbon.

Joe attributes their success to several factors including a mash bill calling for about 60 percent corn.

“We decided to go with a high corn mash bill for the sweetness and the smoothness that it lends, the wheat for sweetness and creamier tones and the rye for spicier notes,” Joe said.

And not just any corn.

“We choose a red variety developed in the 1930s by the University of Wisconsin,” Joe said. “I remember that my dad grew it at one time and sold it to farmers in New York for feed. I was in awe with how beautiful those big red ears were.”

Joe explained that it took three years with help from staff with the Department of Agronomy at the University of Wisconsin and the Wisconsin Crop Improvement Association to propagate enough of the heirloom seed on about 20 acres for the first batch of bourbon that was released in April after being aged for five years.

“The whole process takes time,” Joe said. “We wouldn’t have had the results like we did if we would have rushed the process.”

In March, the family bottled the first batch of bourbon that was distilled in 2009. Joe explained that they decided to invest in the product rather than in a distillery and bottling facility.

In March, the family bottled the first batch of bourbon that was distilled in 2009. Joe explained that they decided to invest in the product rather than in a distillery and bottling facility.

“We were able to age our bourbon longer, which produces a smoother product. We placed our bets and so far it’s paid off,” said Joe proudly.

Another factor that makes their bourbon unique comes during the aging process.

“We converted the former dairy barn into our aging warehouse and it’s not temperature controlled or insulated,” Joe said. “With Wisconsin weather being what it is, it has an effect on the aging process and how the spirits in the barrel move in and out of that wood. The cold makes the wood contract and the summer heat and humidity brings out the spices. We are unique in this respect because not many people age bourbon the way that we do and no two batches will be alike.”

Liz added that they age their bourbon for at least five years and they “don’t bottle it until it is truly ‘ready’.”

Also, during the aging process, the Henrys account for about a 10 to 15 percent loss, which they refer to as the ‘angel’s share.’ Besides the bourbon business, the Henrys also have entered

the agritourism arena by converting the living room of the 1840s farmhouse where Joe grew up into a Tasting Room, which was a feat in of itself to comply with new construction codes.

“We are filling requests for tours and tastings by appointment,” said Liz. “We plan to establish some fixed hours as the holiday season approaches but prefer to know who is coming and when so we can provide the best experience that we can for our customers, family and friends.”

Son Jack works in the Tasting Room when he can and also attends Madison Area Technical College where he is working towards a degree in ag business management and plans to transfer to UW-Madison.

Son Jack works in the Tasting Room when he can and also attends Madison Area Technical College where he is working towards a degree in ag business management and plans to transfer to UW-Madison.

“It’s fun to work with my family on this new business venture and it is a great learning opportunity,” Jack said. “We all contribute to the success and work well together.”

The couple’s oldest son Joe graduated from the UW-Madison School of Business and recently moved to Chicago for a new job. Earlier this year, he helped with a marketing plan and built the initial website for J. Henry & Sons Bourbon and plans on returning home occasionally to help with the family business as it continues to grow.

“After all, people will never stop drinking,” Joe, Jr., laughed. “Craft bourbon hasn’t been too prevalent in Wisconsin and J. Henry & Sons is well placed to fit into a great niche market.”

The Henrys join other Wisconsin distillers including Yahara Bay Distillery, Wollersheim Winery, Great Lakes Distillery and 45th Parallel in New Richmond where Paul Werni also distills bourbon for the Henrys. They are motivated by the fact that the craft distilling industry is expanding in Wisconsin.

The Henrys join other Wisconsin distillers including Yahara Bay Distillery, Wollersheim Winery, Great Lakes Distillery and 45th Parallel in New Richmond where Paul Werni also distills bourbon for the Henrys. They are motivated by the fact that the craft distilling industry is expanding in Wisconsin.

“What better place for this to happen?” asked Liz. “With our strong agriculture values and the Wisconsin work ethic, the craft brewing industry continues to grow and evolve and distilling will very likely follow suit so that Wisconsin will be a creative, food and beverage center.”

The family has had a few months to get used to seeing the product of more than six years of dedicated work on the store shelves. Liz likens it to giving birth.

“A very proud moment but also a little sobering considering its’ future, thinking what have we started? Will they like it? Will it sell? What will we do next and will it continue to be worthy of awards and recognition?” added Liz. “So much to think about.”

For more information, visit www.jhenryandsons.com.

Story by Marian Viney. Original version appeared in the October|November 2015 issue of Wisconsin Farm Bureau Federation’s Rural Route.